Call Us

08045803671

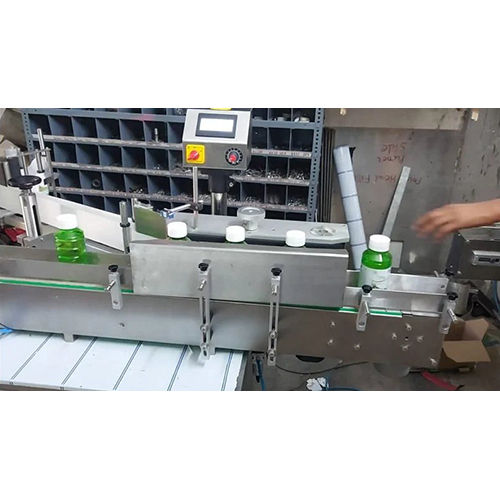

Automatic Sticker Labeling Machine

320000 INR/Piece

Product Details:

- Product Type Sticker Machine

- Material Stainless Steel

- Application Industrial

- Computerized No

- Automatic Grade Automatic

- Control System PLC Control

- Power Source Electric

- Click to view more

X

Automatic Sticker Labeling Machine Price And Quantity

- 1 Piece

- 320000 INR/Piece

Automatic Sticker Labeling Machine Product Specifications

- Stainless Steel

- PLC Control

- Silver

- Touch Screen Simple Control High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Industrial

- Automatic

- No

- Electric

- Sticker Machine

Automatic Sticker Labeling Machine Trade Information

- 10-15 Days

Product Description

We provide technologically good Automatic Sticker Labeling Machine for different requirements of our industrial customers. It is widely used for labeling of round shape products and other related applications. Our offered machine is capable of labeling with partial wrap and full wrap. Made of quality assured components and based on proven technology, this machine provide smooth performance in all conditions. This machine is designed to be cost-effective and safe, easy in nature.

Automatic Sticker Labeling Machine Specifications:

1. Frequency: 50Hz AC Supply

2. Model: SVDL 100/200/300

3. Phase: Single Phase

4. Power Supply: 230 Volt

Sticker Labeling Machine Applications:

1. Food and Beverage Industry: These machines are used to apply labels onto food and beverage containers such as bottles, cans, jars, and pouches. These labels may contain product information, nutritional facts, expiry dates, barcodes, and branding elements.

2. Pharmaceutical Industry: In pharmaceutical manufacturing, precise labeling is crucial for compliance and safety. Sticker labeling machines are used to apply labels onto medicine bottles, vials, ampoules, blister packs, and other packaging formats. These labels often include dosage information, usage instructions, warnings, and batch numbers.

3. Cosmetics and Personal Care Products: These machines are employed to label cosmetic containers, including bottles, jars, tubes, and boxes. Labels on these products typically include ingredients, usage instructions, product names, branding elements, and regulatory information.

4. Chemical and Industrial Products: Sticker labeling machines are used in the chemical and industrial sectors to label containers for various products such as lubricants, solvents, cleaners, and paints. These labels often contain safety warnings, handling instructions, product identifiers, and regulatory compliance information.

5. Automotive and Lubricants Industry: These labeling machines are utilized to label automotive products such as oil bottles, coolant containers, and brake fluid reservoirs. Labels in this industry often include product specifications, usage instructions, safety warnings, and branding elements.

6. Household Products: These machines are employed to label household items such as cleaning agents, detergents, air fresheners, and personal hygiene products. Labels may include usage instructions, safety precautions, branding elements, and regulatory information.

7. Electronic and Electrical Products: They are used in the electronics industry to label components, cables, and devices. Labels may contain product specifications, barcodes, serial numbers, warning symbols, and branding elements.

8. Bottling and Packaging Industry: It play a crucial role in bottling and packaging operations across various sectors, including water bottling, soft drinks, alcoholic beverages, sauces, condiments, and oils.

9. Medical Devices: These machines are employed in the medical device industry to label products such as syringes, catheters, medical tubing, and surgical instruments. Labels may include product specifications, usage instructions, sterilization indicators, and regulatory compliance information.

10. Promotional and Event Materials: These machines are used to produce promotional stickers, event badges, and merchandise labels for branding and marketing purposes across various industries.

Automatic Sticker Labeling Machine FAQ:

Q. How does an automatic sticker labeling machine work?

Ans: These machines typically consist of a conveyor system that moves products through the labeling station. Labels are dispensed from a roll, coated with adhesive, and applied onto the products as they pass by. Advanced machines may include sensors and programmable controls to ensure precise label placement and consistency.

Q. What types of labels can be applied with an automatic sticker labeling machine?

Ans: Automatic sticker labeling machines can apply various types of labels, including paper labels, transparent labels, holographic labels, shrink sleeve labels, and RFID labels, depending on the machine's capabilities and configuration.

Q. What types of products can be labeled using an automatic sticker labeling machine?

Ans: These machines are versatile and can label a wide range of products, including bottles, jars, cans, vials, boxes, pouches, tubes, containers, and packages in industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and more.

Q. What are the advantages of using an automatic sticker labeling machine?

Ans: Some advantages include:

- Increased labeling speed and efficiency compared to manual labeling.

- Consistent and precise label placement, reducing errors and waste.

- Flexibility to handle various label sizes and shapes.

- Integration with other packaging equipment for seamless production lines.

- Reduction in labor costs and improved productivity.

Q. Can automatic sticker labeling machines handle different label sizes and shapes?

Ans: Yes, many automatic labeling machines are designed to accommodate different label sizes and shapes. They may include adjustable guides, labeling heads, and conveyors to adapt to various packaging requirements.

Q. What maintenance is required for automatic sticker labeling machines?

Ans: Regular maintenance tasks may include cleaning, lubrication, inspection of components, and replacement of worn parts such as belts, rollers, and sensors. It's essential to follow the manufacturer's maintenance schedule and guidelines to ensure optimal performance and longevity of the machine.

Q. Are automatic sticker labeling machines easy to set up and operate?

Ans: While initial setup may require calibration and adjustment, modern automatic labeling machines are designed to be user-friendly. They often feature intuitive controls and interfaces for programming label parameters and adjusting settings. Training and support from the manufacturer or supplier can also simplify the setup and operation process.

Q. Can automatic sticker labeling machines integrate with other packaging equipment?

Ans: Yes, many automatic labeling machines are designed to integrate seamlessly with other packaging equipment such as fillers, cappers, sealers, and conveyors. This integration allows for the creation of efficient and automated production lines.

Q. What factors should be considered when selecting an automatic sticker labeling machine?

Ans: Factors to consider include production volume, label size and shape requirements, speed, accuracy, compatibility with existing equipment, ease of maintenance, and budget. It's essential to evaluate these factors carefully and consult with manufacturers or suppliers to choose the right machine for your specific application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free